s.FOX | AI-supported production planning & intelligent production optimisation for Industry 4.0

You want to organise your production and manufacturing planning as efficiently as possible to ensure a successful long-term business performance? Do you want to bring your production orders into an optimal order to ensure better capacity utilisation of your plants? Little FunFact: The production of just 10 products results in 3.6 million possible orders. Add in supply bottlenecks, short-term loss of production capacity, increasing delivery pressure and unplanned staff shortages and you can easily lose track of things.

Want to get rid of your planning and scheduling headaches? Stop wasting time manually updating Excel spreadsheets and start using our intelligent production planning software s.FOX.

Efficient production planning with AI

For manufacturing companies today, creating an efficient production plan and determining the optimal sequence of production orders is more of a challenge than ever before. It requires a lot of time, excellent management and a great deal of experience. Creating efficient production plans in Excel has become virtually impossible today, but is still done by many organisations. Not only is this exercise time-consuming but it also takes up a lot of manpower!

The ever-increasing variety of products and options increases the complexity of the entire production process. Added to this are factors such as distributed manufacturing across multiple locations, sudden influences such as material shortages or rush orders and growing cost pressure in production. Against this background, an efficient production planning and scheduling process that considers the many complex interdependencies has become more critical than ever. Intelligent data analytics based on artificial intelligence and machine learning can help you master the increasing amount and complexity of data and ensure your company’s long-term competitiveness and economic success.

s.FOX was honoured as one of two winners in the ‘Process Excellence’ category – confirmation of the innovative strength and measurable added value of our AI-based production planning.

Our software solution s.FOX

Our production planning solution s.FOX has been specifically designed to master the complexity of the modern manufacturing industry using data science. Our holistic approach and methods help our customers optimise their production processes, reduce costs and increase productivity. s.FOX ensures intelligent sequencing of jobs and production orders and uses artificial intelligence to support complex production planning and scheduling. What used to take hours of manual planning in spreadsheets is now done within in minutes. The software can be used across various industries and guarantees reliable planning of complex Industry 4.0 processes even in the long term. This permits a more efficient cost reduction, optimal use of resources and improved competitiveness. As a real alternative to manual production planning, s.FOX helps you as a manufacturing company to face the future with confidence.

The algorithm library of s.FOX

Using data science, relevant influencing variables called constraints are identified from data sources such as historical production data and master data. But they are also identified in direct dialogue with planners. What’s unique is the combination of AI-based estimators for order-specific process parameters — also called ‘feature importance’ (e.g. setup times) — and powerful optimisers to take into account individual conditions — the ‘constraint satisfaction problem’ (e.g. material or plant availability). This is how we have successfully linked machine learning with powerful optimisation algorithms. The combination of AI and these very algorithms opens up new possibilities for automation and digitalisation of production processes.

The difference between s.FOX and FOX

Diese zwei fast gleichnamigen Softwarelösungen unterscheiden sich lediglich in der Möglichkeit, eine intelligente Produktionsplanung mit oder ohne SAP zu erstellen:

s.FOX

(standalone. Factory Optimization EXcellence):

“Standalone” emphasizes the unique selling point of intelligent production process planning outside or without an SAP connection. In short: s.FOX is for all customers who want to work with an individual connection to other ERP systems or as an introduction to the GIB suite and is available via ifm statmath gmbh.

FOX

(Factory Optimization EXcellence):

Intelligent production process planning in SAP and available via ifm business solutions.

Factors and dependencies in production planning

s.FOX takes into account various factors and dependencies in production planning:

- material availability

- machine capability and availability

- production steps and setup times

- order data

- work plans

- order priorisation

- machine maintenance and planned maintenance intervals

- shift schedules/staff availability

- further customer-specific restrictions

The benefits of s.FOX

- optimal order planning, e.g. to ensure economic utilisation of production lines, improvement of delivery performance and minimisation of setup times

- prioritise orders with maximum flexibility

- forward and backward scheduling possible

- assess the influence of rush orders

- create production plans for multiple locations with different IT infrastructures

- simple planning export

- easy management of interfaces to third-party systems

- flexible, intuitive and clearly structured web application

- high transparency and traceability

- simple software implementation

- consistent quality level of planning (even if planner is absent)

The 5‑step wizard

The simple 5‑step wizard ensures intuitive use and clear visualisation:

STEP 1:

In the first step, select a suitable scheduling strategy from the drop-down menu which reflects the desired planning period as well as your individual production process parameters.

STEP 2:

In the second step, select the machines for which you want to create a plan.

STEP 3:

In the third step, select the orders to be planned.

STEP 4:

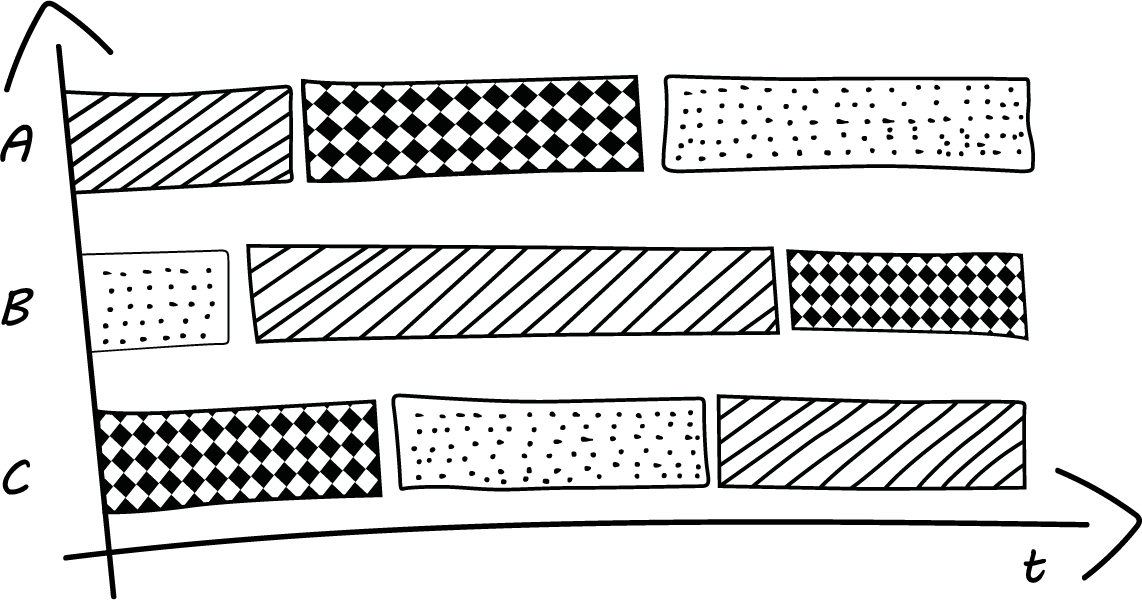

In the fourth step, an optimal plan is presented in an easy-to-follow Gantt chart. Colours, tooltips and key figures can be configured individually.

STEP 5:

In the final step, your custom plan is transferred to your system (e.g. ERP or PPS).

s.FOX in a nutshell

Data:

- order data

- production data

- shift schedules

- material availablity

- relationship data

- work plans

- production process

- ERP data (e.g. SAP)

Our solution for complex production planning

- production planning within minutes, in near real-time and for multiple locations with different infrastructures

- optimal clustering of orders to ensure economic utilisation of production lines

- flexible prioritisation of orders

- ad hoc rescheduling possible

- measurement of crucial KPIs such as setup times etc.

- scenario simulation possibilities

Result:

- intelligent and reliable production planning

- ready-made solution and user-defined programming interface (API) for export to other systems, including SAP

- consistent quality level of planning (even if planner is absent)

FAQ about s.FOX

Deployment and Integration

Yes, this is freely selectable.

A standard pool of objectives is available (e.g., delivery reliability, setup efficiency, workstation utilization). This can be extended upon request.

Functions and Master Data

With the help of s.FOX, well-functioning production plans can be created in a short amount of time.

- AI-supported production planning according to defined optimization objectives

- Management of planning-relevant master data including plausibility checks

- Live plan display with continuous updates in case of disruptions

- Compliance with restrictions (e.g., capacities, material)

s.FOX takes planning to a whole new level: All parties involved always work with the same up-to-date data, ensuring data consistency and quality. Conflicting Excel files and confusing proliferation are a thing of the past, as plausibility checks are integrated directly into the system. The use of AI and optimization algorithms achieves automated and efficient production planning results. This significantly reduces the daily planning effort and saves a considerable amount of time. In the long term, companies also benefit from a sustainable improvement in their KPIs, as processes are continuously optimized and decisions are supported by data.

Yes. s.FOX can be individually adapted to your processes.

- Workstations including efficiencies

- Orders including deadlines

- Materials and work schedules

- Operating calendar (availabilities)

- Setups

IT and Operations

Requirements are customer-specific. Minimum for the optimizer:

- 8 vCPU

- 32 GB RAM

- 32 GB storage

Flexible scaling is possible.

The optimizer runs directly at the customer. Data is not transferred to ifm (except in demo scenarios).

All relevant planning results (start/end times, workstation assignments). Current data can be exported via standard interfaces.

Project Flow and Support

- Demo access with customer data

- Optional pre-project

- Implementation in the customer’s infrastructure

Implementation usually takes about six months, depending on customization and interface requirements

All companies that want to automate their production planning and take it to the next level.

- Standard support: Mon–Fri, 08:00–16:30 (CET), except on public holidays in NRW and from Dec 24–31

- Extensions available upon request

About every three months.

- Via standard interfaces (HTTP, REST, JSON)

- Manual entry in the system

s.FOX provides KPIs on planning results so that developments can be measured over time.

During implementation: a dedicated project manager + deputy.

In live operation: support team.

- Server

- Time for workshops and tests

- Openness to a data-driven approach

Yes. Trainings are held before go-live, followed by an intensive support phase.

Yes. For example:

- Pilot projects in selected areas

- Shadow planning in the new system until full acceptance

Do you have questions about our products? Contact us to book an appointment. Our team will be happy to advise you personally or via email.

Mechanical engineering technician, Materials engineering

Vetter Industrie GmbH